Client: Hinze Dam Alliance

Location: Hinze Dam, Gold Coast Hinterland Queensland

With a rapidly growing population and widespread drought, the pressure on water supply continues to increase.

The Hinze Dam Stage 3 project was designed to increase water storage capacity and delay the release of floodwaters down stream thereby decreasing the number of properties vulnerable to flooding.

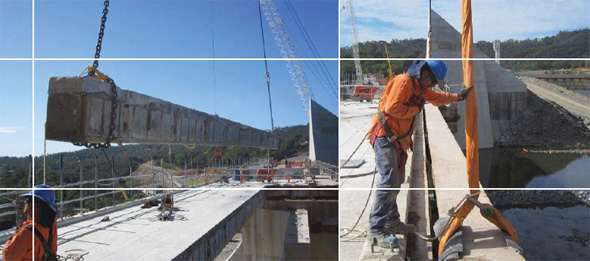

The existing stage 2 spillway bridge consisted of 4 spans totalling 85m in length, with each span made up of 15 pre-stressed beams totalling 9m width. The largest of these spans contained beams weighing 32 tonnes each.

The bridge is situated over the Hinze Dam Spillway and serves as the local traffic access across the dam.

KEY CHALLENGES

Raising the spillway and embankment required the existing bridge to be removed to make way for construction of the new spillway and bridge.

3 – STAGE SOLUTION

- Release Beams

Each of the 60 beams was fastened to the headstock at either end of the abutment using grouted vertical bolts positioned beneath the road slab.

Core drilling was used to locate the bolts and then each nut in turn was removed and replaced with a 25 tonne hydraulic jacking device which pulled the bolt from the head stock. - Separate Beams

Each span of 15 beams was tied together by a topping slab dowelled into the beam.

Total separation of the beams prior to lifting was engineered by a combination of saw cutting and hydraulic splitting. - Remove Beams

Each beam was then hydraulically pushed away from the adjacent beam to ensure total separation whilst providing space for rigging.

All operators and riggers were trained in ‘working at heights’ and a fully qualified demolition supervisor was onsite.

PROJECT SUCCESSES

Combined successfully employed precision cutting and hydraulic jacking techniques to complete the necessary de-construction work safely and efficiently.